Why Packaging Testing Matters

Packaging testing enables companies to get a much better understanding about how their shipped goods will react to different shipping conditions during transit.

Shipping conditions as well as product handling during transit vary tremendously. Shipping goods by air, truck, ship or train presents numerous opportunities for products to be damaged not only by atmospheric conditions but also by physical handling of the products.

Atmospheric challenges include:

- Changes in atmospheric pressures

- Changes in temperature

- Changes in humidity

- Presence of salt or freshwater in the air

- Exposure to adverse weather conditions

- Exposure to intense sunlight and UV rays

Physical challenges include:

- Accidentally dropping packages

- On the corner of the packages

- On the side of the packages

- Intense vibrations of pallets during transportation (bad road conditions)

- Vertical and horizontal movement of pallets (especially on ships)

- Load issues when pallets are stacked

As part of our packaging testing offering, Micom also offers cold chain testing for the pharmaceutical and the food industry.

Packaging Testing Services

Our packaging testing services are recognized by most large North American retailers and industries as we are an ISTA accredited laboratory and operate a quality control system that is ISO 17025 compliant.

Markets

Micom offers packaging testing services to a wide range of industries both in Canada and in the US including:

- Pharmaceutical (GSK Biologics, Genentech, Covidien, etc)

- Food (Kraft, Danone, etc)

- Industrial (Teknion, ABB, Akzo Nobel, etc)

- Electronics (Siemens, Smart Technologies, Nautel, etc)

- Automotive (Spectra Premium, Bombardier Recreational Products, etc)

More Than Just a Test

We go beyond simple packaging testing. Our material testing experts will be happy to discuss your packaging testing requirements and help you decide which tests will better suit your needs. We can test to specific packaging testing protocols or create a custom test program to better suit your particular situation.

We can also review your package damages to help you find timely and cost effective solutions. The insights you gain from packaging testing can help to optimize your packaging itself. By knowing where and how your packaging is vulnerable, will enable you to reduce losses and increase your profitability over both the short and long-term.

Take the Guess Out of the Equation

Micom Laboratories can give you precise numbers so that you can make informed decisions. Our major packaging test equipment includes:

- Random vibration tester

- Incline impact tester

- Drop tester

- Mechanical shaker

- Compression testers

- Climatic chambers

- Clamp tester

- Altitude chamber

- Data loggers

We can test packages and pallet loads for distribution testing. We can also assess individual component mechanical properties:

- Corrugate testing: TAPPI

- Foam testing: ASTM D3574

- Mechanical properties: Material testing

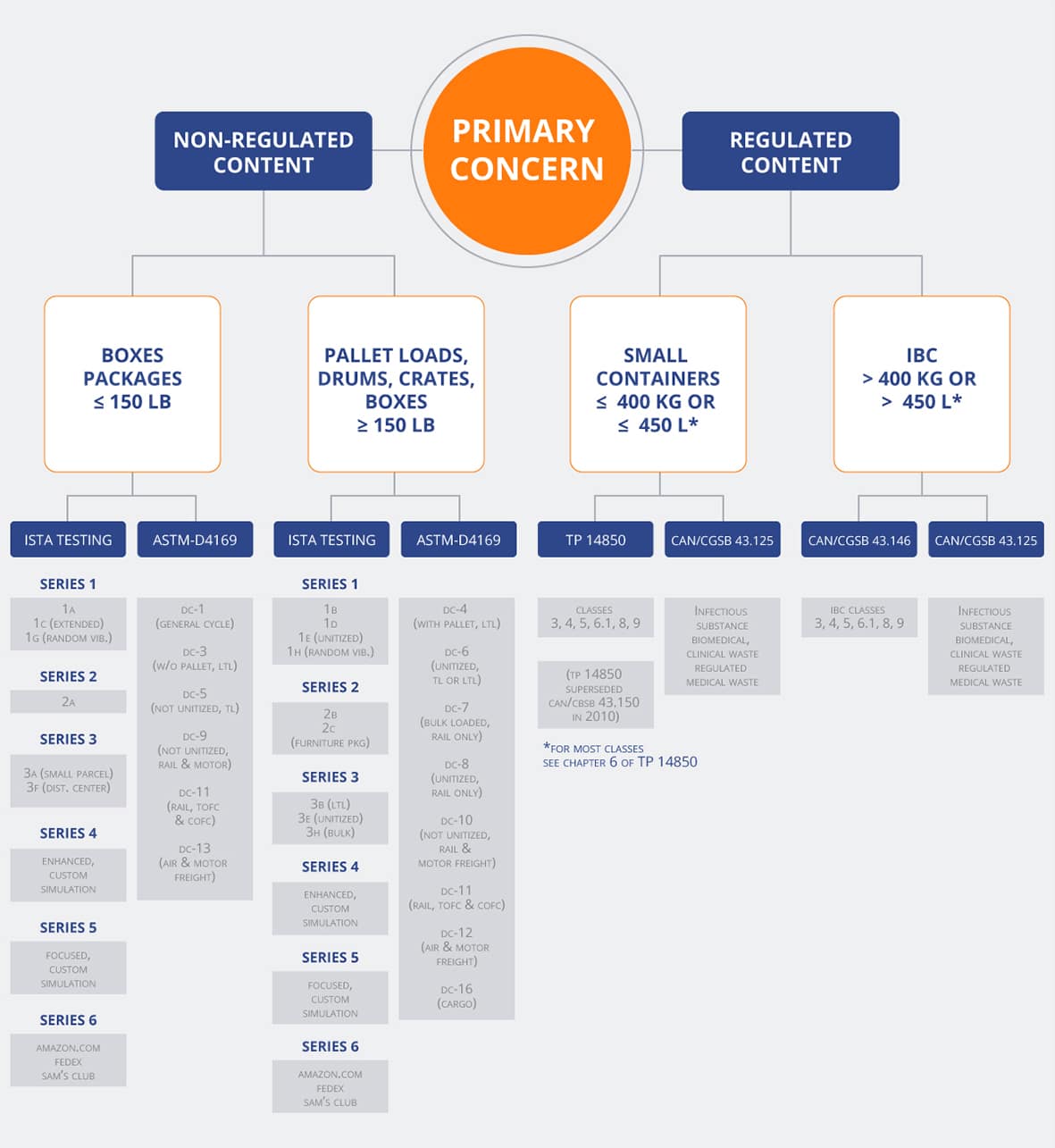

How to Choose the Right Packaging Test

There are numerous tests available that can be used to test the performance and durability of your packages. The following infographic and decision tree will help you better understand how to choose the right package test that is best suited for your goods and your particular situation.

Packaging Testing Infographic

Recognitions

Micom Laboratories is an accredited laboratory. We are recognized by the following organizations for packaging testing services:

- WHO

- ISTA

- WalMart.com

- Transport Canada

- A2LA (QC system + cold chain; ISO 17025, )

- CCSB

- Electrolux